ASSA ABLOY DL6221TA (formerly Crawford) Teledock Autodock

Smooth Telescopic Operation with Electro-Hydraulic Control

This model uses an electro-hydraulic drive system controlled via a semi-automatic interface, enabling efficient and smooth operation. When activated, the platform raises, the telescopic lip extends outward, and the assembly gently lowers to meet the vehicle’s bed. After loading or unloading, the lip retracts automatically and the platform returns to its rest position. Key mechanical elements—including a fixed hydraulic power unit, dual lift cylinders and sturdy telescopic lip guidance—minimise vibration and reduce maintenance needs. Integrated safety props on both sides offer extra protection during servicing.

Flexible Dimensions, High Capacity and Vertical Reach

The DL6221TA is available in standard platform lengths of 2000 mm, 2450 mm and 3000 mm, while widths (the application width) may go up to 3750 mm to accommodate large vehicles. It is rated for a load capacity of 100 kN (10 tonnes) and has a vertical working range that reaches up to 415 mm above dock level and down to 430 mm below, making it suitable for a wide variety of docking conditions and vehicle types. The platform and lip are made from S355 steel with nominal thicknesses of 8 mm (with reinforced 8/10 mm zones).

Telescopic Lip Design and Optional Features

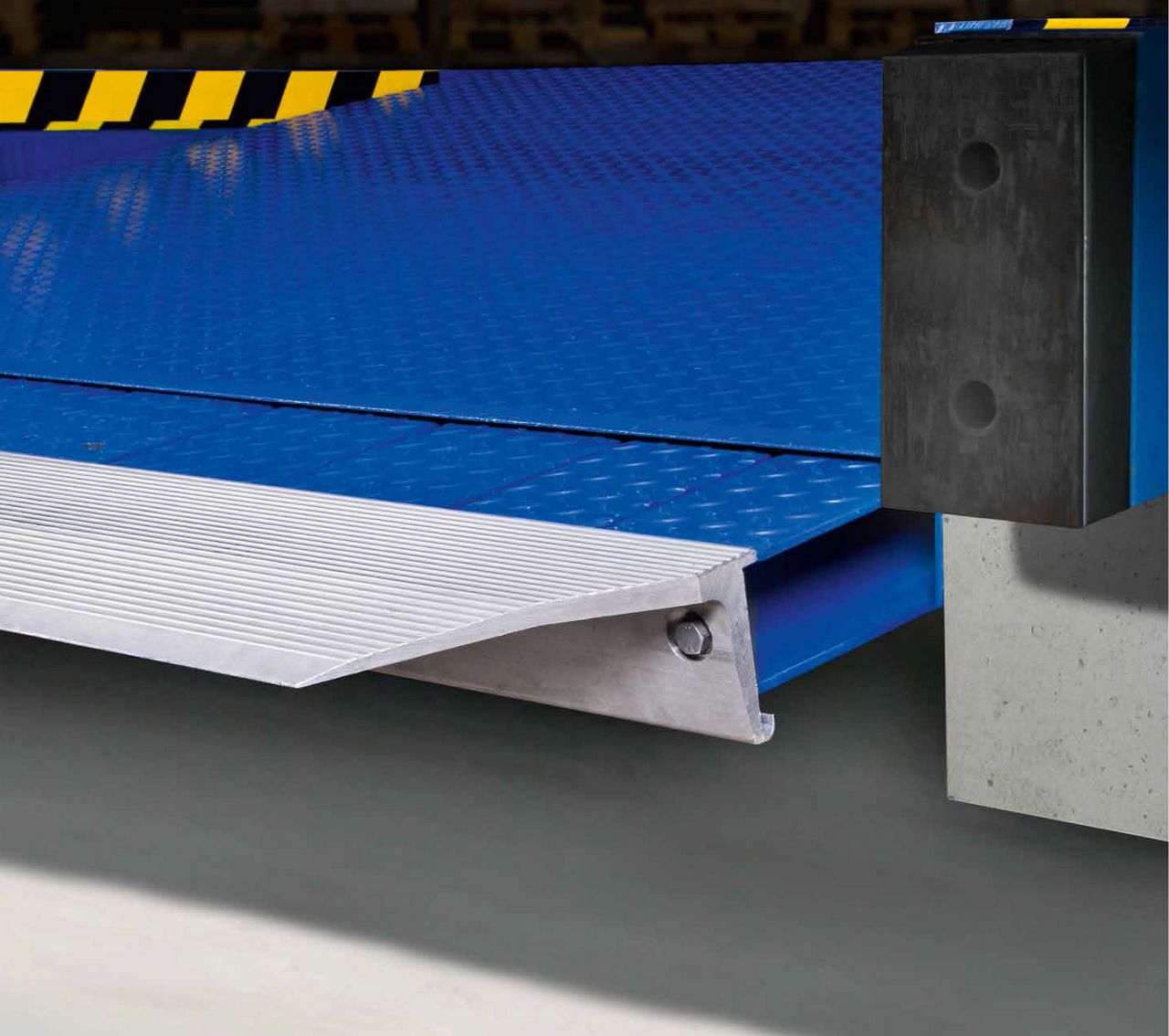

The standard lip is steel and telescopes to 500 mm, with an option to extend up to 1000 mm when extra reach is required. The lip may also be tapered to account for slight misalignment of vehicles and features an 80 mm bevel for smoother transitions. To improve safety and comfort during operation, the platform and lip can be coated with slip-resistant polyurethane, offering an R11 rating and helping to reduce noise while providing robustness against chemical or thermal exposure.

Surface Protection, Corrosion Resistance and Finishes

To withstand challenging environments, the DL6221TA is offered with standard painted finishes in RAL 5010 blue or RAL 9005 black, while other RAL colours are available on request. For more corrosive settings—particularly in coastal areas—the unit can be hot-dip galvanised for enhanced protection. The paint specifications range from C2M up to C5-I, making the product suitable for rural, industrial, or aggressive environments.

Safety, Connectivity and Smart Monitoring

Safety features include an emergency stop system, warning stripes, toe guards, and a free-floating platform position to mitigate risk during operation. The DL6221TA is also compatible with ASSA ABLOY Insight, enabling remote monitoring, diagnostics and operational alerts. This capability helps facility managers proactively manage maintenance, reduce downtime, and maximise operational efficiency.

Accessories, Integration and Lifecycle Support

This dock leveller may be paired with a full suite of loading bay accessories such as buffers, wheel chocks, dock lights, traffic lights and the Dock-IN system to guide vehicle positioning. Through ASSA ABLOY’s Maintain & Optimize service programmes, you can access preventive maintenance, scheduled inspections and tailored support to ensure long-term performance, reduce interruptions and extend operating life.